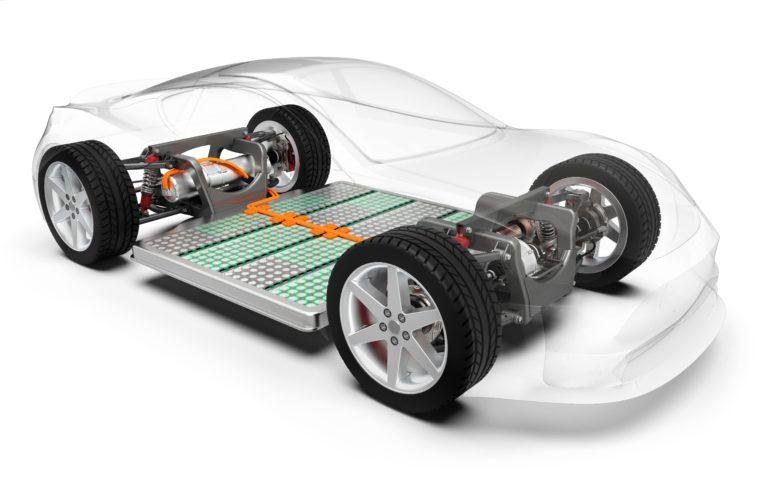

The electric vehicle battery adhesive market is rapidly evolving with continuous innovations that enhance the performance, efficiency, and safety of electric vehicle (EV) batteries. As the automotive industry embraces the electric revolution, battery adhesives have become a critical component in the design and manufacturing of EVs, offering advanced solutions for bonding, insulation, thermal management, and sealing. The increasing demand for EVs and the need for more efficient and durable battery systems are driving several developments in this market.

1. Advancements in Adhesive Technologies

- Continuous research and development efforts are leading to the creation of high-performance adhesives specifically designed for EV batteries.

- Companies are introducing adhesives with superior thermal conductivity, enhanced durability, and resistance to extreme temperatures.

- Innovations like solid-state adhesives are gaining traction due to their potential to improve the overall performance of next-generation batteries.

- New formulations focus on improving bonding strength while reducing curing times, which is crucial for large-scale manufacturing.

2. Focus on Sustainable and Eco-friendly Solutions

- Environmental sustainability is a growing concern, and adhesive manufacturers are increasingly turning towards eco-friendly alternatives.

- Biodegradable and non-toxic adhesives are being developed to meet environmental regulations and consumer preferences for green products.

- The use of solvent-free adhesives is also gaining momentum, aligning with global efforts to reduce harmful emissions during manufacturing processes.

- Additionally, these adhesives support the industry's move towards recyclable and reusable battery components, reducing the overall environmental impact of EV production.

3. Adoption of Advanced Materials

- Adhesives in the electric vehicle battery adhesive market are being designed to complement advanced materials such as lithium-ion and solid-state batteries.

- Companies are utilizing materials like silicone, polyurethane, and epoxy resins to create more flexible and durable bonds that can withstand the unique challenges of EV applications.

- The compatibility of adhesives with lightweight and composite materials is essential for optimizing the overall battery pack performance.

- As battery technology continues to evolve, adhesives are being tailored to meet the increasingly demanding requirements of new battery chemistries.

4. Growing Demand for Lightweight and Compact Battery Solutions

- As the automotive industry focuses on reducing the weight and size of batteries to enhance vehicle range and performance, adhesives are playing a crucial role.

- Adhesives are replacing traditional fasteners and welding methods, offering a lightweight solution for battery assembly.

- The integration of adhesives helps reduce the overall weight of battery packs, contributing to improved vehicle efficiency and range.

- Compact battery designs are made possible by the flexibility of adhesives, allowing for innovative configurations that maximize space and energy density.

5. Development of Smart Adhesives

- The development of smart adhesives that can respond to changes in temperature, pressure, or stress is a key trend in the market.

- These adhesives can provide real-time monitoring of the battery’s condition, alerting manufacturers to potential issues such as overheating or structural failure.

- Smart adhesives are also being developed to enhance the safety features of EV batteries by providing self-healing capabilities, which can repair microcracks or damage in the adhesive layers over time.

- Such innovations are expected to significantly enhance the longevity and reliability of EV batteries.

6. Expansion of Production Capacities

- In response to the increasing demand for EVs, manufacturers of battery adhesives are expanding their production capacities.

- Companies are establishing new production facilities in key EV manufacturing hubs like China, Europe, and North America to meet the growing market requirements.

- The development of localized supply chains is helping reduce lead times and transportation costs, contributing to the overall efficiency of battery pack manufacturing.

- Additionally, automation and advanced manufacturing techniques are being employed to scale up adhesive production while maintaining quality standards.

7. Strategic Collaborations and Partnerships

- Leading adhesive manufacturers are forming strategic partnerships with automakers and battery producers to develop tailored adhesive solutions.

- Collaborative efforts help ensure that adhesive formulations meet the specific needs of different EV battery types, including those with high energy density or unique chemical compositions.

- By working closely with EV manufacturers, adhesive suppliers can better understand the evolving demands of the market and create products that enhance battery performance and safety.

- These partnerships also facilitate the sharing of expertise and resources, accelerating the pace of innovation in the electric vehicle battery adhesive market.

8. Regulatory Developments

- Stringent safety and environmental regulations are shaping the development of adhesives used in EV batteries.

- Adhesive manufacturers are closely monitoring and adapting to new regulatory requirements in different regions to ensure compliance.

- Governments are increasingly focusing on sustainable manufacturing practices, and adhesives that meet environmental and safety standards are becoming a priority.

- Regulatory bodies are also setting stricter guidelines for the thermal management and safety features of EV batteries, which directly influences the adhesive solutions used in battery production.

9. Increasing Investment in R&D

- Investment in research and development is one of the driving factors behind the rapid advancements in the electric vehicle battery adhesive market.

- Adhesive manufacturers are allocating significant resources to R&D to develop cutting-edge technologies that meet the specific needs of the evolving EV industry.

- Companies are exploring new adhesive formulations that offer improved bond strength, resistance to environmental stress, and enhanced performance under varying conditions.

- The growing number of R&D projects focused on EV battery adhesives is expected to result in even more advanced products entering the market in the near future.

10. Regional Market Developments

- The electric vehicle battery adhesive market is experiencing significant growth in key regions such as Asia-Pacific, Europe, and North America.

- In Asia-Pacific, particularly in China, the expansion of EV production facilities is driving the demand for battery adhesives.

- Europe is witnessing a surge in electric vehicle adoption, supported by stringent emission regulations and government incentives, further fueling the need for advanced adhesives.

- North America is also witnessing a rise in EV production, with manufacturers focusing on improving battery performance and safety through the use of high-quality adhesives.