Extrusion coating is a process where a layer of polymer is applied to a substrate material, such as paper, cardboard, metal, or plastic, using an extrusion process. The process involves melting the polymer and applying it as a thin layer over the substrate, providing properties like water resistance, durability, and enhanced strength. It is widely used in industries ranging from packaging to construction and automotive. This article delves into the extrusion coating market, exploring its size, market share, opportunities, challenges, demand, and emerging trends.

Access Full 350 Pages PDF Report @

https://www.databridgemarketresearch.com/reports/global-extrusion-coating-market

Introduction to the Extrusion Coating Market

Extrusion coating is an essential manufacturing process that is used to produce a wide variety of coated materials, which are used across numerous industries. The process begins with the melting of a plastic material, typically polyethylene (PE), polypropylene (PP), or other specialized polymers. This molten polymer is then extruded over a substrate, typically paper, plastic film, or metal. The resulting coated material is often used in applications requiring barrier properties, such as packaging, insulation, and protective coatings.

The extrusion coating market is driven by the rising demand for high-quality, durable packaging materials, which often need enhanced barrier properties to preserve the contents, prevent leakage, or improve shelf life. This process is particularly common in the food and beverage industry, where moisture resistance, durability, and sustainability are key concerns. As industries become more focused on providing long-lasting and eco-friendly products, the demand for extrusion-coated materials continues to rise.

Market Size

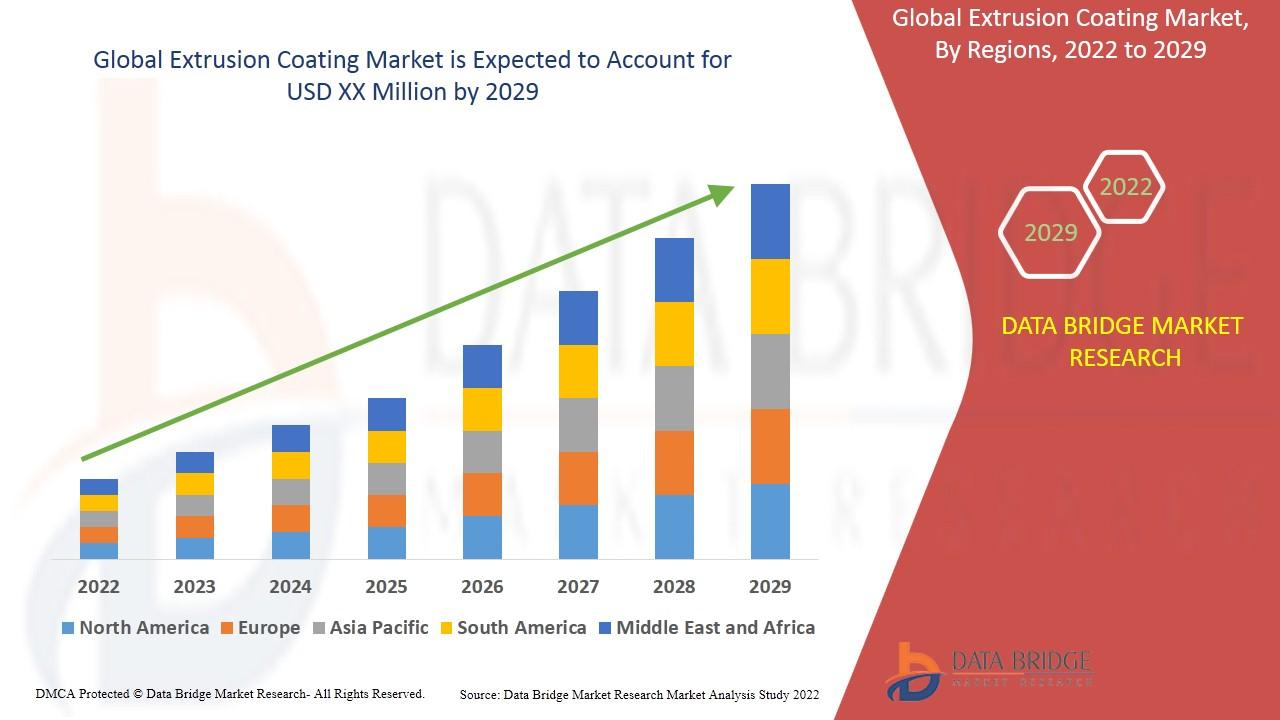

The global extrusion coating market has experienced steady growth in recent years, and this trend is expected to continue. In 2023, the market was valued at approximately USD 10 billion and is projected to grow at a compound annual growth rate (CAGR) of 5% from 2024 to 2030. The market's growth is primarily attributed to the increasing demand for high-performance coatings in various industries, including packaging, automotive, construction, and consumer goods.

The packaging sector, in particular, accounts for a significant portion of the market, driven by the need for more efficient, sustainable, and long-lasting packaging solutions. The demand for extrusion-coated materials, such as paper-based cartons, laminated bags, and flexible films, continues to rise, especially as manufacturers focus on improving product shelf life, reducing spoilage, and increasing environmental sustainability.

Regionally, North America and Europe hold significant shares of the extrusion coating market due to the presence of well-established industries and high demand for innovative packaging solutions. However, the Asia-Pacific region, particularly China and India, is experiencing rapid growth due to increasing industrialization and a rising demand for packaged goods. This makes Asia-Pacific a key region for future market expansion.

Market Share

In terms of market share, extrusion coating is widely used in the packaging sector, which takes up a large portion of the market. The key materials used for extrusion coating include polyethylene (PE), ethylene-vinyl acetate (EVA), polypropylene (PP), and polystyrene (PS). Among these, polyethylene (PE) is the most commonly used polymer in extrusion coating due to its low cost, ease of processing, and excellent barrier properties against moisture, air, and other contaminants.

Several key players dominate the extrusion coating market, including companies such as Dow Chemical Company, ExxonMobil Chemical, and Borealis AG. These companies offer a wide range of polymer resins used in extrusion coating applications. They continue to lead the market due to their strong research and development capabilities, well-established distribution networks, and ability to innovate with new materials. Additionally, there are numerous smaller, regional players who cater to specific niches within the industry.

Market Opportunities and Challenges

The extrusion coating market presents a variety of opportunities for growth, as well as challenges that companies must navigate to remain competitive.

Opportunities:

-

Sustainability and Eco-friendly Solutions: With growing environmental concerns, the demand for sustainable and recyclable materials is increasing. Extrusion coating technology can play a vital role in producing eco-friendly packaging materials. Companies that invest in biodegradable and recyclable coatings, such as bio-based polyethylene or water-based coatings, are well-positioned to capture a larger share of the market.

-

Growth of E-commerce: The rapid expansion of e-commerce and online retailing has led to an increase in the demand for packaging materials that can withstand the rigors of shipping and handling. Extrusion-coated materials are ideal for packaging products that require durability, protection, and moisture resistance. As online shopping continues to grow, the demand for extrusion-coated materials in the packaging sector is expected to increase.

-

Innovations in Packaging: As consumer demand for high-performance packaging grows, manufacturers are focusing on creating more advanced extrusion-coated materials with enhanced properties. For example, the development of coatings with improved barrier properties against oxygen, moisture, and light is opening up new markets in the food and beverage industry, where product shelf life and freshness are critical.

-

Automotive and Construction Applications: In addition to packaging, extrusion-coated materials are increasingly being used in automotive and construction applications. For instance, in the automotive industry, extrusion-coated materials are used for protective films, automotive components, and insulation materials. The construction industry also utilizes these materials for energy-efficient coatings and insulation products, providing additional opportunities for market growth.

Challenges:

-

High Production Costs: The extrusion coating process can be costly, particularly when using high-performance polymers and resins. While the raw materials are essential to ensure quality, the expense of these materials can pose a challenge for manufacturers, especially small to mid-sized businesses looking to remain competitive. Reducing production costs while maintaining high quality is a constant challenge.

-

Fluctuating Raw Material Prices: The price of raw materials such as polyethylene, polypropylene, and other specialty polymers can fluctuate due to changes in oil prices, supply chain disruptions, and geopolitical factors. These price fluctuations can significantly impact the profitability of manufacturers in the extrusion coating market.

-

Technological Advancements and Competition: While technological advancements present opportunities, they also create intense competition within the market. Companies that do not keep pace with new developments in extrusion coating technology risk falling behind. The demand for higher-quality, more innovative coatings is increasing, and manufacturers must invest in research and development to stay competitive.

-

Regulatory Challenges: As governments around the world implement stricter environmental regulations, manufacturers are under increasing pressure to adopt sustainable practices. Complying with these regulations requires investment in new technologies, processes, and materials, which can add to the cost of production.

Market Demand

The demand for extrusion-coated products is primarily driven by the growing need for high-performance packaging materials. In particular, the food and beverage sector is a significant driver of market demand, as products such as juice cartons, snack bags, and other food packaging require coatings that can provide moisture and oxygen barriers to extend shelf life. Additionally, extrusion coatings are increasingly used in other industries such as automotive, electronics, and consumer goods, where protective coatings are necessary for durability and strength.

The push for sustainable solutions is also influencing demand, as manufacturers seek recyclable, biodegradable, or eco-friendly coatings. The rise in e-commerce and online retailing further boosts the demand for extrusion-coated materials used in packaging, as they provide a protective barrier during transit.

Market Trends

Several key trends are shaping the future of the extrusion coating market:

-

Sustainability and Eco-friendly Packaging: With growing awareness of environmental issues, the extrusion coating industry is focusing more on sustainable materials. Biodegradable and recyclable coatings are gaining traction, particularly in the packaging industry, where consumer demand for eco-friendly solutions is at an all-time high.

-

Advancements in Coating Technologies: Innovations in extrusion coating technologies, such as improvements in multilayer coatings, are helping companies enhance the performance of their products. These advancements are focused on creating coatings with better barrier properties, improved resistance to heat and chemicals, and enhanced surface adhesion.

-

Smart Packaging Solutions: The rise of smart packaging, including technologies such as RFID (radio frequency identification) and QR codes, is also influencing the extrusion coating market. These coatings enable enhanced consumer interaction and product tracking, especially in the food and beverage sector.

-

Shift Towards Bio-based Polymers: As part of the movement toward more sustainable solutions, there is a growing interest in bio-based and renewable materials in the extrusion coating process. These materials not only offer an eco-friendly alternative but also help reduce the environmental footprint of the manufacturing process.

Conclusion

The extrusion coating market is poised for steady growth, driven by increasing demand for high-performance packaging, innovations in coating technologies, and a focus on sustainability. The market presents numerous opportunities, particularly in sectors such as e-commerce, food packaging, automotive, and construction. However, challenges related to raw material costs, competition, and regulatory compliance remain. Companies that focus on technological advancements, cost reduction, and sustainable practices will likely emerge as leaders in the growing extrusion coating market.

Browse Trending Reports:

Veterinary Clostridium Vaccine Market

Far Field Speech And Voice Recognition Market

Farbers Disease Drug Market

Dc Motor Control Devices Market

Chronic Depressive Personality Disorder Treatment Market

Adams Oliver Syndrome Market

Cancer Supportive Care Drugs Market

n Methyl 3 Pyrrolidone Market

Crosslinking Agent Market

Molecular Quality Controls Market

Paper Band Market

Epidermolytic Ichthyosis Market

Hemolytic Anemia Market

Cortical Necrosis Market

Bronchodilators Market

Biological Seed Treatment Market

Engine And Transmission Thermal Systems Market

Antimicrobial Packaging Market

Automotive In Wheel Market

Bread Improvers Market

Antibiotics In Aquaculture Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975